Our process

Pool Resurfacing Preparation

A fibreglass pool needs to be thoroughly prepared before work can begin on its restoration. Part of that preparation involves stabilising the shell so that it is not damaged further while being emptied.

Preparation is crucial in the building industry, swimming pool resurfacing and renovations are no exception. All of the below pool interior finish types can be resurfaced with fiberglass. However, each finish requires a tailored surface preparation process.

- Marblesheen

- Pebblecrete

- Quartzon

- Painted concrete

- Fully tiled

- Vinyl liner

- Besser block or formed and poured

- Fibreglass moulded shells

For example, painted pools are sandblasted, pebblecrete pools are resin screeded to make smooth, and vinyl liners are removed and the concrete base is acid washed. In addition, fibreglass moulded shells are thoroughly ground back to remove oxidised gelcoat and blistering of poor quality resins.

1. Primer Coat

Primer coat seals the surface and provides excellent adhesion of subsequent layers. Particularly important for concrete or porous substrates.

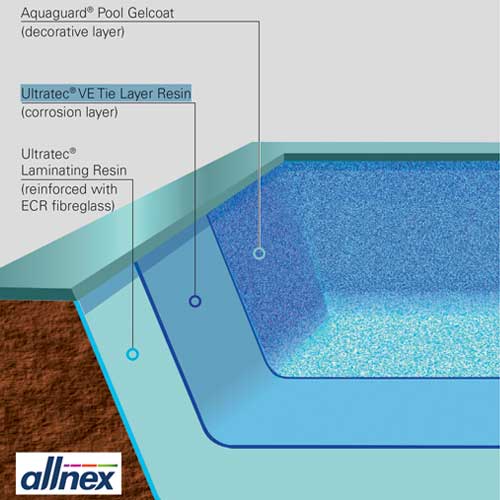

2. Resin Layer Coat

A layered coat of resin is applied to entire pool. Provides a corrosion barrier to protect the pool from osmosis. Each pool is unique and requires varying layers of fiberglass matting applied, depending on the structural strength required. The resin in then reapplied and saturated over the fiberglass matting to reinforce and become one with the fiberglass, providing superior chemical, water and osmosis resistance.

3. Fill Coat

Once the fibreglass laminate has fully cured, a Vinyl Ester Fill Coat is applied. The fill coat ensures any small holes or imperfections are filled. It not only acts as a secondary layer, but also a secondary corrosion barrier providing additional opacity and prevention against fibre wicking. Once the fill coat has cured, this layer will be lightly ground back to remove any imperfections in preparation for the Top Coat.

4. Top Coat

The Top Coat contains UV stabilised colour pigment, helping resist fading and ensures colour retention. This coat also ensures a colourful, decorative and protective barrier for your swimming pool. Resulting in a spectacular pool!

5. Tapping off the pool

Either Frank or Mat will return to inspect the completed project. All necessary fittings and valves will be placed back into the pool. You will then be advised when the pool is able to be refilled, generally 7 days after completion.

Repair and restoration of fibreglass pools

Possible problems

If you’ve had your pool for a longer period of time, you may begin to notice some problems. Most of our customers contact us with one of the following problems:

Osmotic Blistering – This occurs when air or contaminated water seeps through the pool’s lining, causing the surface to develop small bubbles or blisters. If left like this for too long, algae growth can also occur.

Flaking – Also known as “chalky” because of the white powdery residue it creates, flaking occurs when the topcoat or protective barrier becomes brittle over time and starts to break away.

Cracking – Fibreglass is generally tough, however fiberglass pools can be susceptible to cracking, especially when they are empty. It generally occurs when pressure on a given point of the shell exceeds the gel coat’s ability to flex.

Drumminess – This occurs when water penetrates through the barrier surface and causes a separation between the pool’s concrete structure and the top surface.

Calcium or Black Spots – In both these instances, a growth can be seen on the surface of the pool. These spots can’t be removed by scrubbing or application of chemical products.

Peeling Paint – Some pools were originally finished with a smooth render that was then coated with pool paint. Peeling of that paint, especially after many years, is a common occurrence with concrete pools.

User Comfort – Some customers also want a different finish because surfaces like marblesheen and pebblecrete are rough and abrasive to swimmers.

Get In Touch for a FREE QUOTE

Use our inquiry form below and one of our staff will get in touch.

Call Frank

FRANK: 0425 220 147

Call Mat

MAT: 0414 697 787